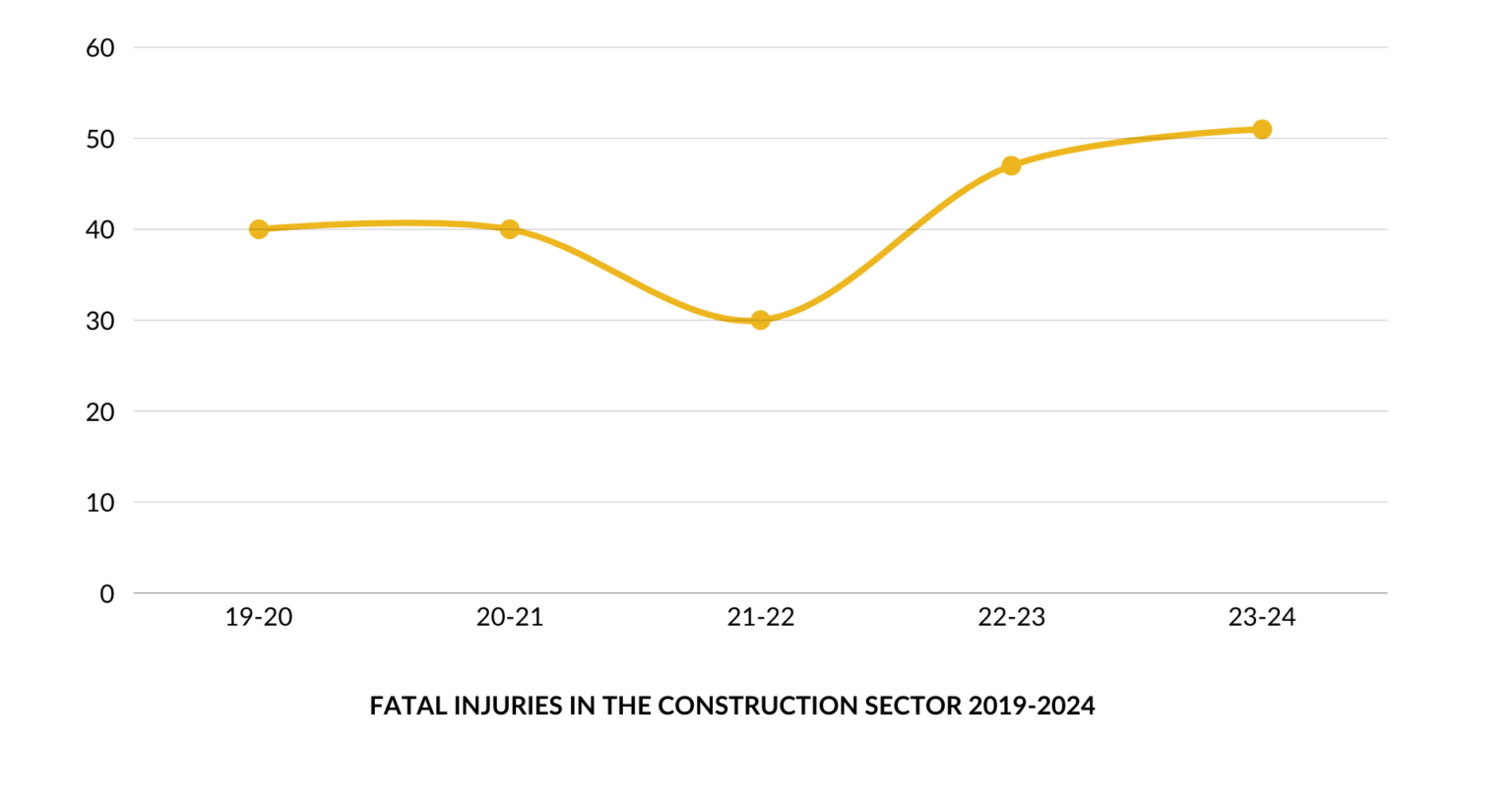

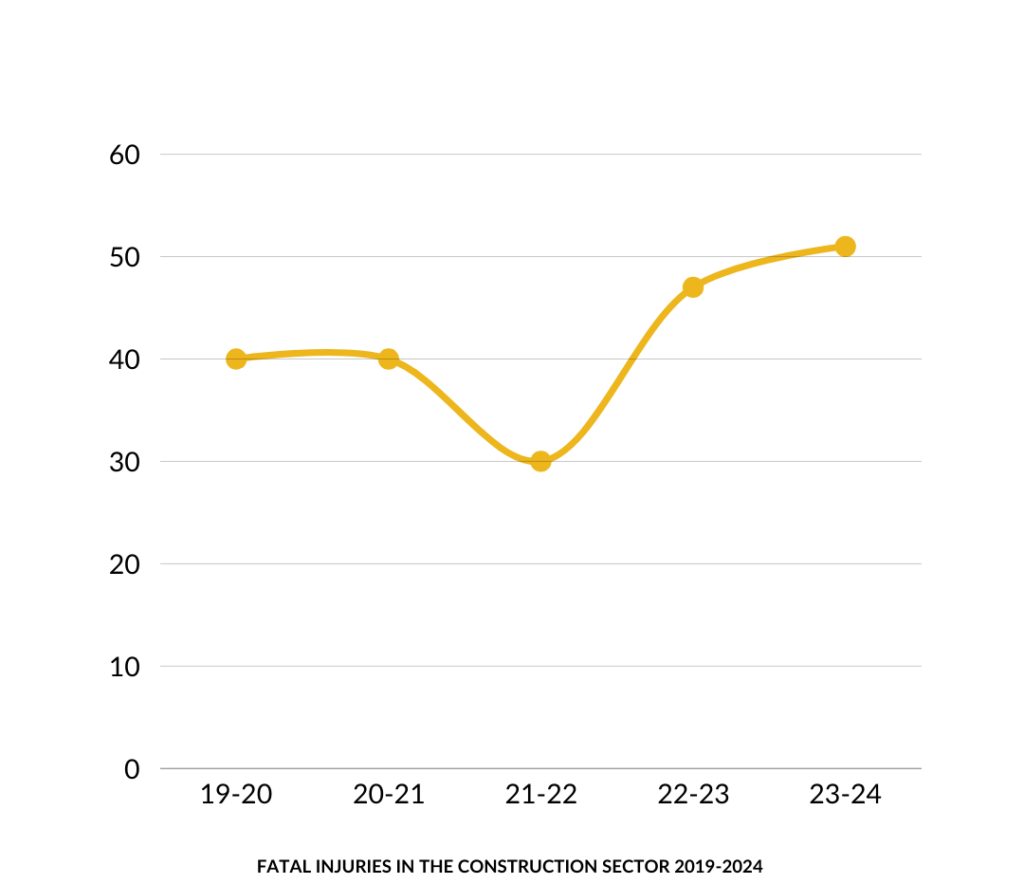

In high-risk environments like Formula 1 (and Construction), safety isn’t a luxury; it’s the lifeline of the entire operation. The tragic losses of racing legend Ayrton Senna in 1994, and Jules Bianchi in 2014 uncovered critical gaps in F1’s safety framework, driving transformative changes that continue to save lives today. In Construction, where worker fatalities have surged by 70% over the last five years (Construction News, 2024), a similar urgency for proactive measures is essential to avoid future tragedies.

What can Construction learn from Formula 1’s safety evolution?

F1 demonstrates that safety advancements can’t just be reactive; they require a sustained commitment to continuous improvement and innovation. While high-profile tragedies often serve as catalysts, the real lesson lies in preventing accidents before they happen. For the construction industry, this means a cultural shift towards innovation-driven safety practices and a refusal to accept risk as a byproduct of the job.

Senna’s Death: The Moment that Transformed Formula 1

Ayrton Senna’s fatal crash at Imola was a turning point for Formula 1, shaking the motor-racing world to its core and forcing a deep reassessment of its approach to safety. Before this, the sport had accepted a level of risk that left drivers vulnerable. But Senna’s death shattered this norm, driving the FIA to rethink everything from track design to driver protection.

Key safety innovations introduced after Senna’s death:

- Stricter Track Layouts with enhanced runoff areas and strategic barriers were introduced to protect drivers in high-risk zones.

- Improved Crash Barriers to minimise impact (G) force, reducing the risk of fatal accidents.

- The HANS Device: This head and neck support device, now mandatory, prevents severe spinal injuries during crashes.

Bianchi’s Crash and the Need for Organisational Overhauls

Jules Bianchi’s crash at the Suzuka Grand Prix in 2014 exposed another gap, this time in race protocol and management. Unlike Senna’s crash, which highlighted technical weaknesses, Bianchi’s death underscored the dangers of flawed decision-making. A recovery vehicle was deployed in a risky corner amid hazardous conditions, ultimately costing Bianchi his life. In response, Formula 1 implemented:

- Enhanced Race Management Protocols: Updated rules for vehicle recovery and race management during adverse weather.

- The Halo Device: This driver-protection structure, tested before Bianchi’s crash, gained widespread support and became a staple of F1 safety thereafter.

The tragic events in Formula 1 underscore a vital truth: waiting for a crisis to spur safety improvements is too costly. In Construction, where preventable incidents (from falls to equipment mishaps) are still far too common, a similar shift towards proactive, technology-driven safety practices is essential.

The Grenfell Tower disaster serves as our own industry’s wake-up call, much like Senna’s crash did for Formula 1. Grenfell’s tragedy exposed deep-rooted flaws in building safety standards and enforcement, prompting the release of the Building Safety Act. This act represents a step toward embedding a safety-first culture, but for lasting change, we need to push beyond regulatory compliance. The construction industry must actively integrate safety innovation into daily practice, just as Formula 1 transformed its approach to protect drivers long before they reached the track.

Adopting Technology for Continuous Safety Innovation

Construction, like Formula 1, has the potential to harness technology for continuous safety improvement. Here’s how the industry can implement a proactive approach:

- Digital Training: Offering digital safety training and periodic briefings can keep teams informed, engaged, and accountable for their safety practices.

- Real-Time Inspections: Allow for instant reporting and compliance tracking, enabling rapid response to hazards as they arise.

- Data Analytics: Centralised dashboards with real-time safety metrics and predictive analytics allow us to detect patterns and foresee risks.

- Feedback Mechanisms: Digital tools that empower workers to report safety concerns or suggest improvements, fostering a culture of ongoing safety enhancement.

Creating a Safety-First Mindset

At innDex, we believe that great outcomes aren’t just achieved by implementing the latest technology. By educating workers on the role of digital solutions in enhancing safety and efficiency, and how technology can empower them rather than replace them, we can build a safety culture that not only adopts new tools but embraces them.